Micvac

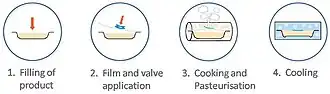

The Micvac system is a pasteurization method for the food processing industry producing ready meals. Food ingredients are inserted into a package, which is sealed. A small hole is pierced in the sealing film. The package is cooked and pasteurized in the microwave tunnel. During this process, the package works like a small pressure cooker, allowing oxygen and some steam to escape through the small hole in the film. Once steam and oxygen have left the package during cooking, the valve is applied, creating a natural vacuum. The process time is short since the food is pasteurized with microwaves. When the microwave heating process stops the valve closes. Remaining steam condenses and causes an underpressure in the package. The final result is a cooked, pasteurized and vacuum-packed product. The short cooking time in combination with the absence of oxygen in the pack is unique for the method and has many advantages. The method has been used in the food industry since 2005.

The inventor of the technique is Dr. Joel Haamer and the company Micvac was founded in August 2000. In the 1970s, when Haamer was seeking a solution for better taking care of mussels, which are heat-sensitive and easily become rancid, he first began to conceive the method. In the end of the 1990s, the microwave technology had reached a stage where Haamer's idea was patented. For five years the development work took place and then, in 2005, the method was commercialized.

References

- Lindqvist, Helen (2008). Influence of Herring (Clupea harengus) Intake on Risk Factors for Cariovascular Disease. ISBN 978-91-7385-136-7.

External links

- Micvac is mentioned on the website SIK - the Swedish Institute for Food and Biotechnology. Note! In swedish

- Programme; 5th International Thermal Processing Conference: new thermal technologies. Organized by CCFRA (Campden and Chorleywood Food Research Association)