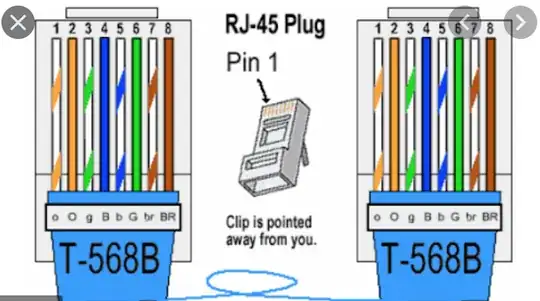

Once you've adopted a wiring standard (568B in your case), you should maintain it throughout your installation.

Wall plates are simply a convenient break in a run of cable, so pin 1 should follow with the same colour through each pin 1 all the way from end to end, etc. In your picture you'd be following the outer columns marked 'B' for the faceplate connections. If you did ever need a crossover connection this would be better handled by the final interconnect cable rather than cross wiring a wall plate, though in practice either approach would work.

Historically crossover cables were used when connecting directly bewtween similar devices (PC to PC, or Switch to Switch), allowing Receive to be connected directly to Transmit, whereas conventional connections (PC to switch) are already wired internally to handle that mapping. However nowadays any compliant Gigabit devices are required to sense and auto-negotiate an internal crossover when required, so there's no more need to use crossover cables when cascading modern switches.

It's fairly important to maintain the pair twist as far as possible, more so in higher bandwidth installations, so try to keep the pairs twisted all the way up to the punch down in the wall plate (or into the strain releif if you're fitting your own RJ45 ends). The pairs are actually twisted at different rates to minimise cross talk between pairs (brown pair usually has the slowest twist) so don't go mad and twist the ends like a tie wrap.

UTP cable comes in many variants (STP, UTP, Cat5, Cat6, solid core, multi strand, etc). In my experiance for a casual domestic installation it won't matter too much if these are mixed, and typically you'd use solid core for infrastructure (in walls behind faceplates) because it's better for the signal and once installed isn't prone to being flexed to cause fatigue fractures in the single copper strand. Whereas you'd use multistrand in any patch leads which are subject to repeated bending, they may still fracture individual strands but will be overlaid by adjacent strands to maintain continuity. I mention this because the punch down connections in the back of a faceplate will readily displace the wire insulation on a solid single core, but can sometimes fail to penetrate the insulation on the more flexible multistrand, so if you use multistrand into the faceplate try to keep it taut as you punch, and punch down repeatedly to ensure a good connection.

You can only be really sure of success across all pairs by using a continuity tester.

HTH