The PSU chassis is ground

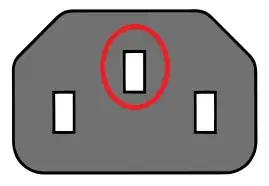

If you have a multimeter (or a continuity tester), you can probe your power cable to figure out what's connected where. What you'll find is that the ground prong from your outlet is connected to the middle hole on the computer side of the cable.

Image by Museo8bits, Public domain, via Wikimedia Commons, with added annotation.

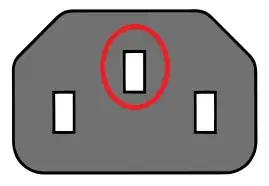

This matches up with the center pin in the receptacle in the PSU (A). If you then opened the PSU and looked at the back side of that pin, you would find it turns into a green-and-yellow wire (B) that travels a short distance before being bolted to the inside of the PSU chassis (C).

Images taken by the author. CC0 license.

This means that the PSU chassis is not just a ground, it is the ground. The only way to ground anything is by connecting it, at least indirectly, to the PSU chassis. And normally, your computer's metal case is bolted to the PSU's metal chassis, which means the case is also a ground. By using a wooden case, you'll lose that case ground.

There is another "ground"

That said, your motherboard normally receives a lot of power from the PSU, and that power has to go somewhere. That "somewhere" is normally the 0v (black) wires that plug into it from the PSU. These can also take static shocks away from the motherboard, but using a metal case has some advantages:

- When you work on the motherboard, one of the first things you're likely to do is unplug the power connectors from it. You'll probably do it by grabbing the plastic connector, which won't ground you at all. And you'll likely do that before ever touching the motherboard. Which means the motherboard is likely to be disconnected from 0v by the time you shock it. It's much more likely to still be touching the case when you finally touch the motherboard directly.

- When you open a metal case, odds are high that you'll touch the case while attempting to get it open, which means you'll probably ground yourself by accident before you get anywhere near the motherboard. Wood is non-conductive, so even if you spend an hour touching your case before you open it, you'll still have your static charge.

- The 0v wires get rid of electricity by sending it out the neutral wire in your house (the exit point for electricity). When you turn off the power switch on the PSU, it interrupts the hot wire (the entry point for electricity). When wiring outlets, it is extremely easy to switch hot and neutral by accident without ever noticing. If you ever plug your computer into such a mis-wired outlet, turning off the switch will interrupt neutral instead, which will leave your 0v wires disconnected and useless. In contrast, ground wires and their connectors are both made to stand out, so they're much more often connected right.

- If you only have one ground, then you only need one ground to fail before your electronics are in danger. If you have two grounds, then both of them have to fail before your electronics are in danger.

The case ground offers some important benefits, so you can have a wood case, but you'll need to compensate for the missing case ground if you want to have the same static discharge protection.

Feedback for your proposal

The only obvious flaw I see in your plan for conductive glue and a metal sheet is that the metal sheet needs a connection to the PSU chassis. If it were me, I'd attach a conductive metal sheet to the inside of the wood case, drill holes in it for the motherboard stays, then attach it to the PSU chassis with a fat green or green-and-yellow wire. The color is important. Ground is always green or green-and-yellow.

You might have to drill an extra hole in the side of your PSU to bolt the ground wire to. I would highly recommend taking the shell off your PSU before you drill any extra holes in it. Putting a small hole in the shell isn't a big deal, but hitting the electronics can kill you (via house fire). Puncturing the big capacitors might not be fun either. You'll also want to be sure the back side of the screw won't interfere with anything important. So it's important that you can see what you're drilling into.

I'd also be thinking about how to mount the hard drives in metal as well - they need ground protection too. And optical drives. If it's metal, and it's normally touching your computer's case, it probably needs to be grounded.

I'd consider building a prototype and paying attention to how and where I touch the case while I open it. Then I'd think about putting some grounded metal accents there to maintain that property of accidentally grounding myself whenever I open the case.

A comment by Theodore mentioned that you might want to be concerned about protecting people from electric shock. This is normally a critical function of grounding, but you're in a special case where electrocution isn't an issue. Most of your computer's contents are low voltage DC, which is safe to touch. The high voltage AC, which is dangerous, will be safely contained inside the PSU's chassis, which is grounded. As long as you aren't making a wooden PSU chassis too, you shouldn't have any raised electrocution hazard.

His points about electromagnetic radiation are worth considering though. Grounded metal is a lot better at stopping EMR than wood is. A wooden case might make nearby sensitive electronics more likely to misbehave, or might make your computer more sensitive to outside interference. In the unlikely event that your computer is too noisy, you might get a visit from the local radio authorities demanding you shut it down. Properly addressing that might involve putting wall-to-wall metal inside your case.

An alternative idea

At this point, you might want to consider another approach: Buy an otherwise boxy case with a fat face plate (so optical drives stick out the front), tear off all the trim, and build a wooden case around it. Make it so you pull off the wood case's side, then open the inner metal case's side. You might have to embed the lights and power button in wood instead of metal, but lights are wrapped in plastic and expendable, while power buttons are too chunky to suffer from the occasional static shock, so that's okay.

The inner case will give you all the proper grounding and EMR shielding of metal for the expensive stuff, while your outer one will give you the canvas you need for your new laser engraver.