Microtomes

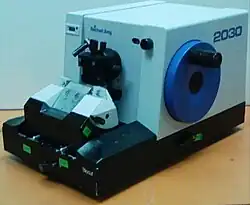

Biocut 2030 microtome, Cambridge Instruments GmbH, Reichert-Jung

Principle of Operation

Two motions are significant in operation of a microtome. (1) is motion of the blade past the knife to cut a section. (2) is advancement of the specimen to adjust section thickness. Motion (1) is by a brass cylinder sliding in a brass barrel. This comes from rotation of a micrometer screw in the center of the cylinder relative to a nut in the cylinder. In the biocut2030, rotation of the nut with the screw stationary positions the specimen relative to the knife. Rotation of the screw with the nut stationary moves the cylinder toward the knife by a section thickness. Advance of a section thickness occurs at the end of the upward motion of the specimen, preceding motion (2). Motion (2) occurs by vertical motion of the sliding block holding the barrel. The block is held by rollers running in a pair of tracks.

The microtome market[1] is undergoing a significant transformation due to rapid advancements in laboratory automation and precision engineering. Modern laboratories are adopting advanced microtome systems such as rotary microtomes, cryostat microtomes, and ultramicrotomes to enhance tissue sample preparation.

Operation

Operation of a similar machine is addressed in a video at YouTube.

Troubleshooting

| Malfunction | Explanation | Corrective Procedure |

|---|---|---|

| Sections inconsistent in thickness | Release torque for Belleville spring clutch connecting lever to screw or torque for nut to cylinder is is insufficient. | Adjust Belleville clutches. |

| Coarse feed (small handwheel) seems tight | Friction between micrometer screw and nut or between nut and cylinder. | Remove barrel and cylinder. Remove micrometer screw, clean and apply fresh grease. Remove nut from cylinder, clean and reassemble with fresh grease. Check nut torque and adjust if required. Reassemble. |

| Hex wrench can not turn socket cap screw to remove it. | Socket in screw head is rounded out. | Turn with a cross-pinned socket. |

Adjust Belleville clutches

Follow these steps in sequence.

- Remove knife block, specimen holder and cylinder head.

- Remove cowling.

- Remove barrel-cylinder assembly from sliding block.

- Remove cylinder from barrel.

- Adjust clutch between lever and spindle.

- Adjust clutch between cylinder and nut.

- Replace cylinder in barrel.

- Replace barrel-cylinder assembly in sliding block.

- Replace cowling

- Replace cylinder head, specimen holder and knife block.